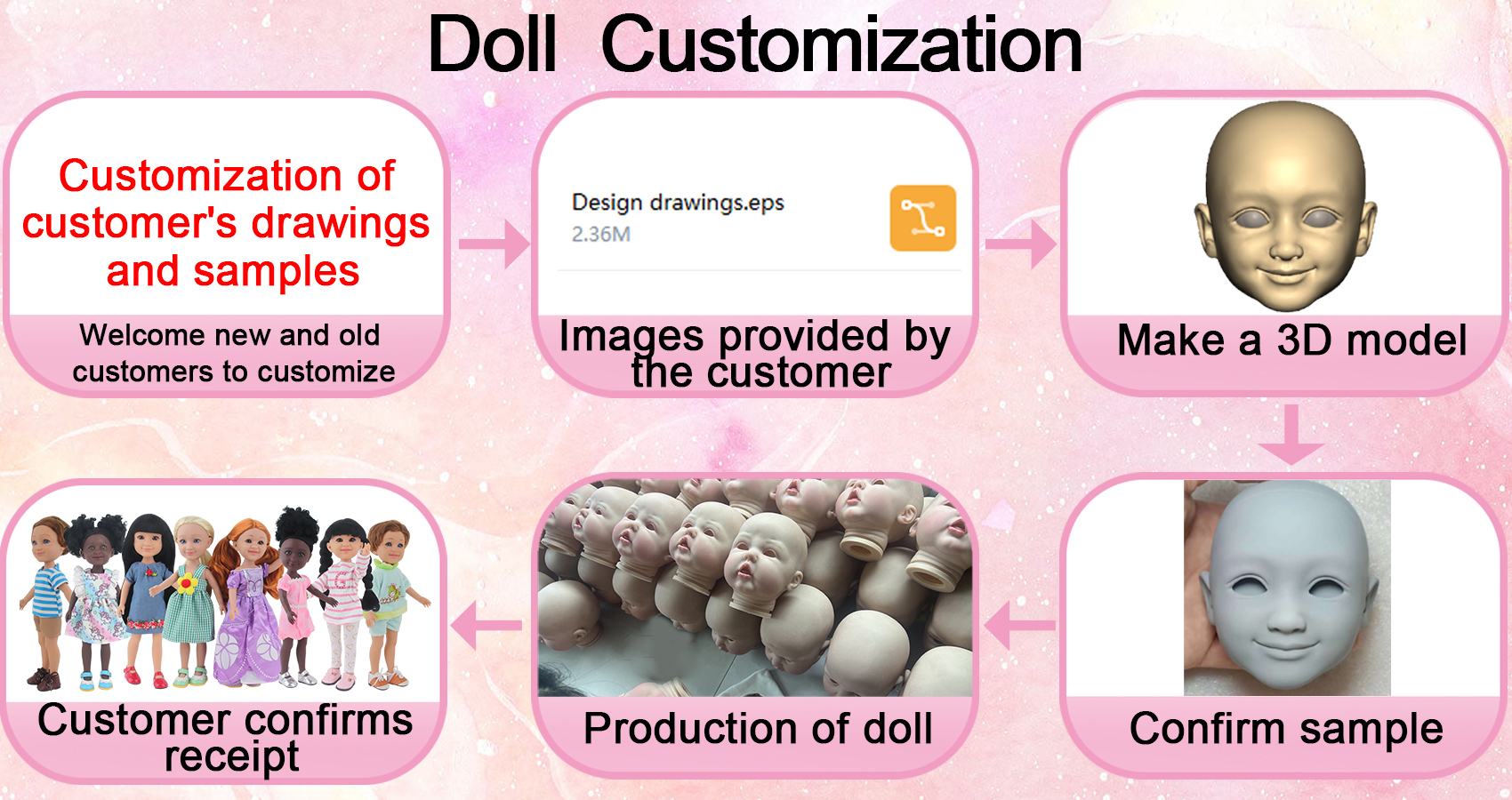

The production process of silicone dolls indeed involves a series of meticulous steps to ensure the creation of a high-quality and lifelike product. Let’s break down each step:

1. Design Phase: Understanding the customer’s requirements and preferences is crucial. This involves determining the size, shape, features, and overall appearance of the doll. Designers may use computer-aided design (CAD) software to create a detailed blueprint.

2. 3D Modeling: Once the design is finalized, a 3D model of the doll is generated. This step helps ensure accuracy and allows for adjustments to be made before moving forward with production.

3. Material Preparation: Silicone material, known for its flexibility and durability, is prepared for injection molding. This involves mixing the silicone with any necessary additives to achieve the desired properties.

4. Injection Molding: The prepared silicone material is injected into the mold that was created based on the 3D model. Injection molding allows for precise replication of the desired shape and features of the doll.

5. Hardening Process: After the silicone is injected into the mold, it undergoes a hardening process. This step is crucial for achieving the desired softness or hardness of the doll’s body parts, as specified by the customer.

6. Painting and Detailing: Once the doll is removed from the mold and has undergone hardening, it is painted and detailed to enhance its lifelike appearance. This may include applying blush, lipstick, freckles, and carefully crafting hair.

7. Final Finishing Touches: After painting and detailing, the doll undergoes final finishing touches to ensure quality and consistency. Any imperfections are addressed, and adjustments may be made to optimize the doll’s appearance.

8. Packaging: The completed doll is carefully packaged to protect it during transportation and delivery to the customer. Packaging may include protective wrapping, foam inserts, and a box or case designed specifically for the doll.

Throughout each step of the production process, precision, attention to detail, and craftsmanship are essential to ensure the creation of a high-quality silicone doll that meets the customer’s expectations.